Our projects and products

An overview of what we can do for you

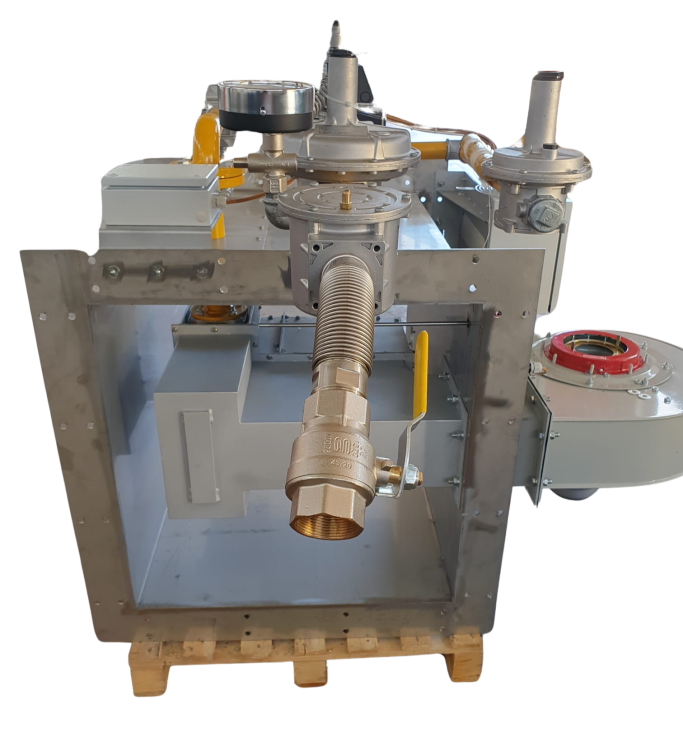

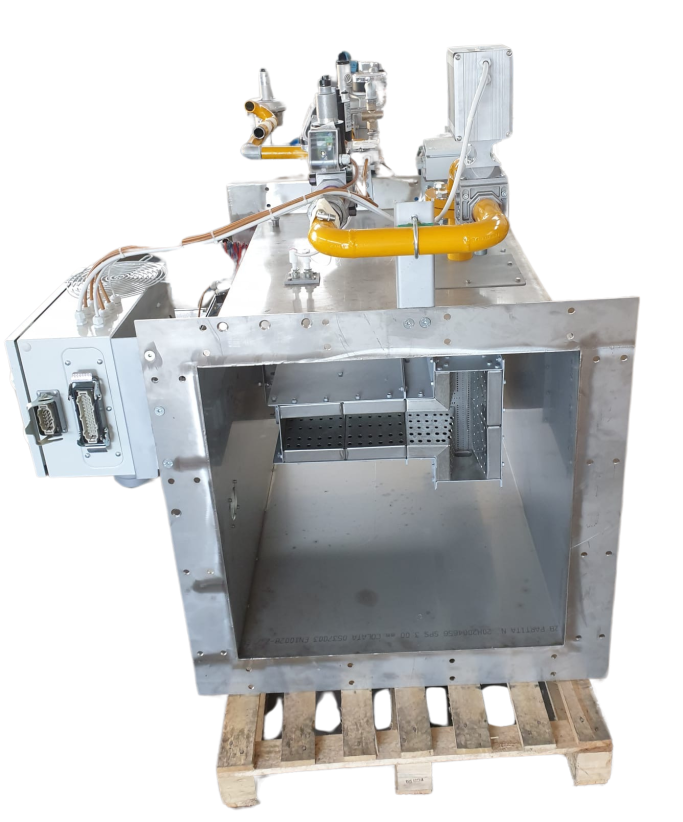

BVA Hot Air Gas Generator

The BVA (air vein burner) generator is a machine designed to produce heat to be fed directly into a stream of air to be heated and, because of its versatility, can be used for multiple purposes and installed directly in the recovery pipeline, becoming part of it.

Other construction solutions allow the BVA to be placed in the sidewall of masonry air ducts or on the walls of mixing chambers.

The BVA generator consists of a gas burner capable of operating in an air vein and a carpentry structure that forms the machine frame, as well as the combustion air distribution rail.

The generator's burner is modular in design to allow versatility in construction to accommodate all types of requirements.

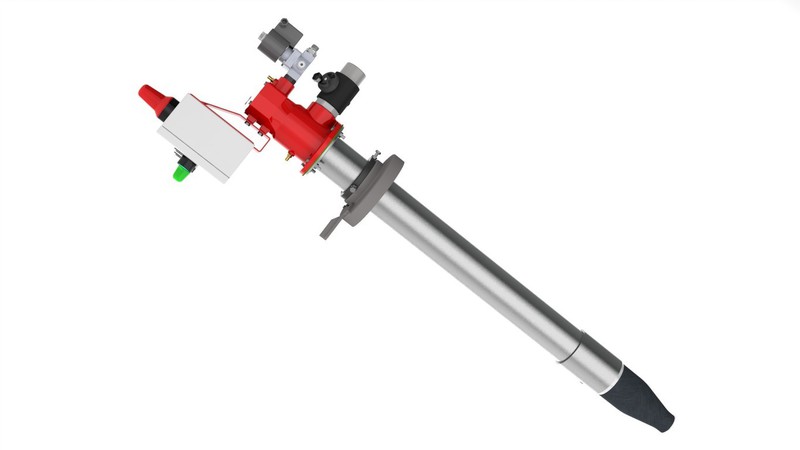

Gas Burners

Sirio - Fiamma - Turbo Jet

The main component of natural gas is methane (CH4), the smallest and lightest among the molecules of hydrocarbons.

It also normally contains heavier gaseous hydrocarbons such as ethane (CH3CH3), propane (CH3CH2CH3) and butane (CH3CH2CH2CH3), and, in small quantities, pentane.

Energy power: The combustion of one cubic meter of commercial type of natural gas generally produces about 38 MJ (10.6 kWh). More precisely, we have:

- Higher heating value: 13,284 kcal / kg or 9530 kcal/Nm³

- Lower heating value: 11 946 kcal / kg or 8570 kcal/Nm³

The gas burners / feeders in various versions, mono, dual fuel, pulse, can function with preheated combustion air from 150 °C to 500 °C.

The various models of the series implement the “flameless” combustion for the ULTRA LOW performances (NOx<100mg/Nm3 – Tair=500°C @1200°C).

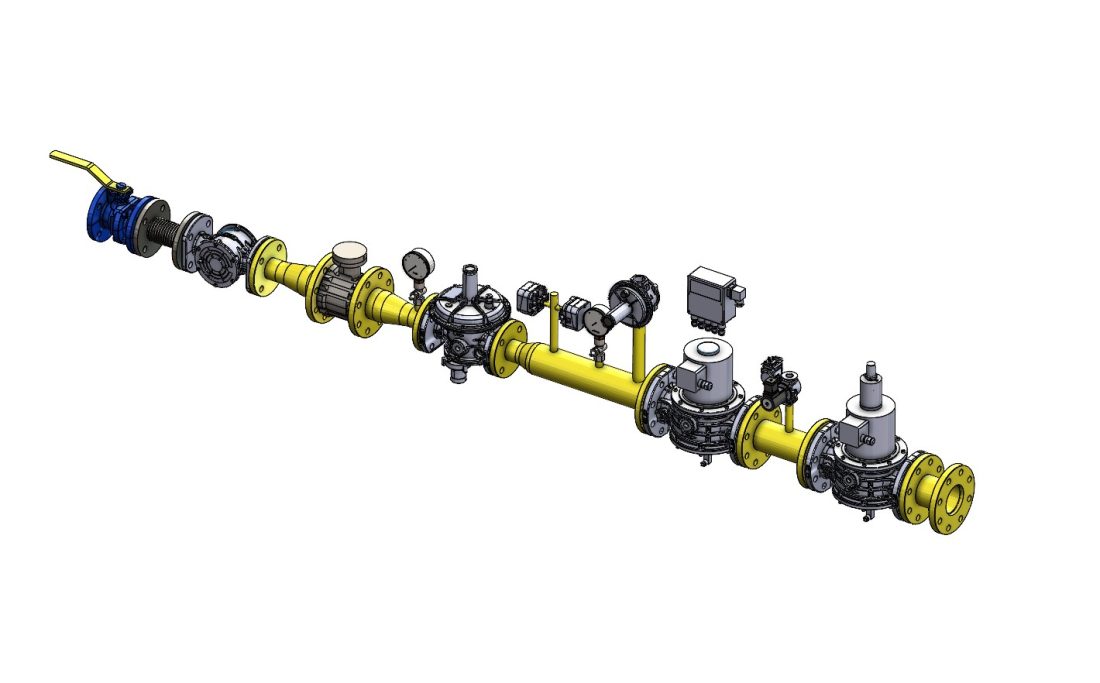

Gas Reduction/ Interception Ramp

The GAS REDUCTION / INTERCEPTION ramp is mounted upstream of the burner group, near the point of use, and has the function of controlling and guaranteeing a given gas pressure and blocking the supply when required.

Heavy & Light Oil Burners

SUPERTEC AIRFUEL: it is a liquid fuel feeder to be fitted in the ceiling of the kilns for heavy clay industry. The high infiltration capacity both at the bottom and in the middle of the stacked products makes this machine to be indispensable for the preparation and temperature rise in the first firing zone. Thanks to the mixing of air-fuel, the elimination of any unburned residues present in the smokes is allowed. The fuel sent to the pipes by means of a pumping and dosing circuit is injected at low pressure and sprayed by means of the mixing with air which is blown at high speed. In automatic mode, the maintenance of the predetermined temperature is maintained by an electronic control system that controls the modulation.

SUPERTEC IMPULSE: feed units for heavy oil or diesel with cyclic circuit impulse type. Fuel introduced under pressure, even up to 80 bar, by a pump and sent to the individual injectors by means of a distributor unit.

Solid Fuel Burners

The use of a particular type of solid fuel burner is intimately linked to the type of kiln on which the burner is installed. Coal as well as pet coke or biomass products are cheap fuels and widespread in many countries of the world. India is one of those. Today, coal as fuel for kilns in India is generally used badly with coarse feeding systems with large and uncontrolled size of its particles. As a result an inefficient combustion, strong atmospheric pollution, high consumption, considerable workers effort, extremely hard work, is obtained. The use of a modern solid fuel burner makes possible to check the air / fuel ratio which is near to the stoichiometric ratio, also minimum quantity required as a function of the internal temperature of the furnace, reduction and perfect control of fuel granulometry. It is logic: reducing the granulometry of coal approaches it to gas characteristics with more efficiency in the combustion.

MULTIJET SYSTEM - SELF GRINDING SYSTEM - CENTRALIZED GRINDING

Hybrid Burners

The power supply group consists of a natural gas duct, two ducts (supply and return) for heavy oil, a combustion support air duct, and a series of air/gas & heavy oil injectors, uniformly arranged on the top of the tunnel furnace in two rows relative to the central body. Along the natural gas branch pipe, there is a manual valve, an on/off solenoid valve, and a modulating valve controlled by an electronic actuator. Along the heavy oil branch pipe, there is a filter, a preheating resistor for the oil, a motorized pump, a distributor controlled by a DC motor, and a series of dosing drawers serving each injector. The combustion air duct uses a motorized control valve and a series of manual valves. A thermocouple installed at the center of the burner group will transmit the temperature value to the burner’s control panel. After comparing the collected signals with the required temperature values, the on-board control panel sends instructions to the "HYBRID OIL TURBOGAS" oil & gas feeder, directly to the gas modulating valve, or for oil combustion, to the rotary distributor motor. A mechanical link between the modulating damper of the combustion air and the gas modulating valve allows for a continuous air-fuel ratio. Alternatively, it is possible to control the centrifugal fan motor via an inverter. There are also manual ball valves on the air pipe to support the combustion of each injector.

The "HYBRID AIRFUEL TURBOGAS" burner group operates in the furnace zone where the internal ambient temperature of the tunnel furnace is higher than the autoignition temperature of the gas or fuel oil. The equipment includes temperature detection and control, internal piping, internal electrical cables, internal control, combustion fan, air and gas and heavy oil ducts, switches, valves, instruments, and accessories.

Abbiamo bisogno del vostro consenso per caricare le traduzioni

Per tradurre i contenuti del sito web utilizziamo un servizio di terze parti che potrebbe raccogliere dati sulla vostra attività. Si prega di rivedere i dettagli nell'informativa sulla privacy e accettare il servizio per vedere le traduzioni.